Would you consider the act of recording a penalty notice for a contractor’s failure to collect trash… an inspection?

Most wouldn’t. But that’s the problem.

We tend to view inspection through a narrow lens, as a maintenance task, a checklist, a formality to confirm that assets are functioning or safe. In reality, inspection is something much more fundamental: it’s the structured capture of data from the field.

That act of observing, documenting, timestamping, classifying, and escalating is the essence of inspection. Whether it’s a technician logging joint integrity data during a shutdown or a project officer flagging a missed waste collection on a city street, inspection is about structured awareness. And when that data is captured digitally, in real time, it becomes operationally transformative.

Forward-thinking organisations are starting to embrace this broader definition. They’re applying inspection workflows to compliance, service delivery, production analytics, and governance, not just maintenance.

This article is an invitation to rethink how you define inspection. Through three real-world case studies, from contractor enforcement and flange management to downtime tracking, we show how digital inspection is being used in unexpected ways to drive performance, transparency, and strategy.

Because once you stop seeing inspection as maintenance… you start seeing it as intelligence.

Inspection = Structured Data Collection

To unlock the full value of inspections, we must stop thinking of them as activities for maintenance and start thinking of them as structured data capture events.

A modern, digital inspection is not a checklist. It’s a data transaction, timestamped, asset-linked, and context-rich. Every submission builds a body of field intelligence: typed inputs, captured photos, severity ratings, geolocation, user attribution, and more. When performed through a configurable, no-code platform like Inspectivity, inspections become live, auditable nodes in an operational dataset.

This is where the real power lies.

By shifting from passive documentation to active data collection, inspections enable a wide spectrum of value creation:

- Contract enforcement: Automate thresholds, trigger alerts, and validate SLAs with transparent evidence.

- Operational analytics: Track trends, identify outliers, and benchmark performance across teams, sites, or contractors.

- Predictive planning: Use clean inspection data to fuel analytics or support data-informed maintenance cycles.

- Audit and governance: Provide instant, defensible records that eliminate dispute and delay.

Legacy systems bury inspection outcomes in PDFs and spreadsheets. In contrast, digital inspections can be queried, visualised, and acted on in real time. A single data entry in the field can:

- Alert supervisors to a failed task.

- Feed dashboards that track asset health or compliance gaps.

- Support contractors in submitting corrective actions.

- Serve as evidence in an audit or investigation.

Structured inspection data is more than a record. It’s a shared operational language, one that allows field teams, engineers, compliance officers, and executives to collaborate around a common source of truth.

And perhaps most importantly, this shift isn’t about digitising maintenance. It’s about liberating inspection from maintenance altogether, and recognising its role as a data engine for everything from enforcement to strategy.

Three Case Studies That Prove It

Case Study: Waste Management Compliance: Enforcing Standards at Scale

The Problem

A major government environmental authority in the Gulf region faced significant operational and compliance challenges while managing its network of waste contractors. The authority employs more than 100 inspectors across eight operational zones, each responsible for ensuring contractor adherence to key performance indicators (KPIs) covering street cleanliness, vehicle condition, workforce readiness, and safety practices.

However, the inspection process was heavily manual. Paper forms and spreadsheets served as the main tools for recording non-compliances, leading to a host of problems:

- Field data was delayed or incomplete

- Photographic evidence lacked intelligent labelling and clarity

- Issued penalties lacked an audit trail due to inconsistent documentation

- KPI Rectification windows were difficult to manage with a lack of real-time information

- Project officers had limited visibility into issue lifecycles and resolution

The absence of a centralised, transparent system led to fragile audit trails and increased the risk of non-enforcement. Without structured workflows, the client struggled to ensure timely corrective action or demonstrate accountability.

The Solution

To overcome these issues, the authority implemented the Inspectivity Platform as its digital compliance system. Inspectivity’s no-code capabilities enabled a tailored rollout across all eight zones, with each regional team receiving customised inspection templates that reflected their specific contractual requirements.

Inspectors now use mobile tablets to log observations in the field. KPI issues are raised in real time, with timestamped photo evidence and penalty classifications. These records immediately sync to the cloud, triggering automated alerts based on predefined thresholds. Crucially, the system introduced:

- Automated escalation if the rectification windows expired

- Role-based access for inspectors, project officers, and contractors

- Structured audit trails with user attribution for every action

- Contractor portals for submitting rectification evidence

The Result

Twelve months post-deployment, the improvements are clear:

- Over 316,000 KPI non-compliances recorded

- 658,000+ media files uploaded as supporting evidence

- More than AUD 136 million in penalties tracked and managed

Project officers gained visibility into issue resolution timelines, while inspectors no longer had to chase paperwork. Contractors can be more responsive, aware that oversight is continuous and supported by unambiguous data.

Why It Matters?

This transformation reframed this type of “inspection” from a reactive activity into a real-time enforcement mechanism. The data integrity and auditability achieved through digital inspection elevated the authority’s compliance posture, enabling faster decisions and fairer outcomes. For the first time, multiple stakeholders operated from a single source of truth, and field inspections became a strategic input into governance.

Case Study: Flange Management During Shutdown: Digitising Critical Workflows

The Problem

An engineering team within a major oil and gas services company faced challenges in coordinating the high-pressure workflows associated with flange management. Whether for planned interventions, ongoing maintenance, or campaign-based activities, the integrity of flanged joints is critical for operational safety, equipment reliability, and schedule adherence.

Historically, flange activities were managed with paper-based checklists and spreadsheets. This approach made it difficult to:

- Capture joint-specific inspection data at the point of activity

- Maintain consistent documentation across varied teams and tools

- Trace QA steps and technician credentials

- Deliver real-time oversight for project leads and decision-makers

The lack of live visibility and data standardisation hindered the company’s ability to manage flange work efficiently, especially when work scopes included hundreds of joints across multiple locations.

The Solution

To address this, the company deployed Inspectivity’s platform and collaborated with its Professional Services team to build a digital-first flange management system. Five structured templates were configured to capture all phases of flange activity, including:

- Flange specs and component data

- Initial condition checks and damage observations

- Torque and tensioning information

- QA reviews and technician sign-offs

Each flange was assigned one or more boundary identifiers, allowing for flexible grouping by work zone or system scope. All data was captured in the field via mobile devices and synced in real time to the Inspectivity Platform.

Dashboards built in Power BI enabled live tracking of flange progress:

- Joint statuses (Assembled, Disassembled, Repair Required)

- Machining outcomes (Repair Completed vs Required)

- Joint categories (Planned, Witness, Unplanned)

- Visual overviews of progress by location or scope

The Result

The implementation delivered immediate and measurable improvements across operational, QA, and supervisory workflows:

- All flange joints were digitally tracked by status and boundary

- Technician credentials and QA validation were recorded for every joint

- Dashboards surfaced live insights on bottlenecks, machining needs, and progress

- Structured templates ensured consistent data capture across all work types

Supervisors no longer needed to rely on spreadsheets or ad hoc updates. With mobile capture and real-time dashboards, engineering and QA leads gained the ability to make confident, data-backed decisions throughout the campaign. The company now operates from a unified digital framework for flange management that is scalable across future work scopes.

Why It Matters

This case highlights how digital inspection can unify and standardise a complex, high-volume process. By digitising flange management, the client reduced administrative overhead, accelerated QA reviews, and created a single source of operational truth.

Importantly, the configuration became the client’s intellectual property. Their internal workflows and standards were codified into reusable templates, allowing future flange management campaigns to be launched with speed and confidence.

This approach is not just about modernising checklists. It is about building a scalable, data-centric inspection model that supports field teams, engineers, and management with the information they need at the moment it matters most.

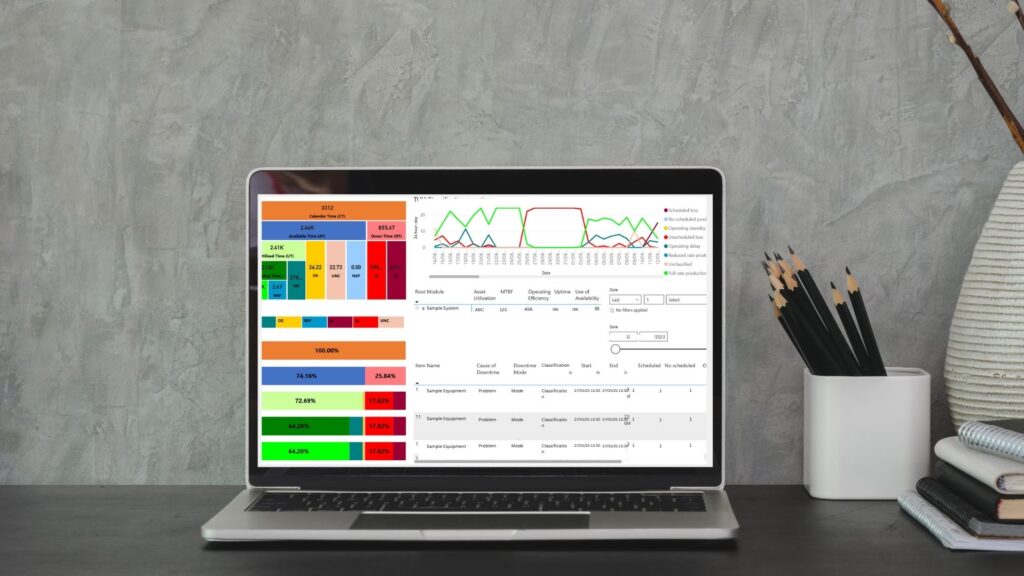

Case Study: Downtime Visibility: Turning Guesswork into Strategy

The Problem

A large industrial operator managing several production sites was struggling to answer a fundamental question: Where are we losing time, and why?

Downtime events were recorded inconsistently, if at all. Operators relied on handwritten notes and Excel sheets, with each site using different terms and templates. Data was often incomplete or missing key context, like cause, duration, or the asset impacted.

This fragmented approach resulted in several pain points:

- Poor visibility into asset performance across the network

- Inability to benchmark or compare sites

- Missed root causes and delayed corrective action

- Manual, reactive reporting with limited strategic value

Without a structured way to track downtime, site leads and planners were left guessing about the source of the lost efficiency.

The Solution

To address these challenges, the operator deployed the Inspectivity Platform to digitise and standardise downtime logging.

Using the platform’s mobility app, field teams began capturing downtime events at the point of occurrence. Each event included the cause, duration, impact, and supporting photos. All entries were automatically linked to the relevant asset through the platform’s multi-tiered hierarchy, providing full operational context.

A structured time usage model was introduced, segmenting every hour into defined categories such as full-rate production, performance loss, operating standby, and scheduled or unscheduled downtime. This provided consistency across all sites and enabled reliable reporting.

To support decision-making, an automated ETL pipeline was configured to feed this data into Power BI dashboards. This integration enabled:

- Real-time visibility of downtime events

- Cross-site performance benchmarking

- Faster and more accurate root cause analysis

- Evidence-based prioritisation for maintenance and planning

The Result

The transformation delivered immediate results:

- Over 2,000 downtime events logged so far with structured metadata

- More than 15,000 hours categorised using a consistent time usage model

- Manual reporting was replaced at seven production facilities

- Operations and maintenance teams are aligned around a shared data source

Downtime inspections have shifted from low-value admin work to a strategic data stream. Leaders can now understand trends, respond faster, and focus resources where they are needed most.

Why It Matters

This case study demonstrates that the real value of digital inspection lies in its ability to generate structured, high-confidence data.

The platform’s no-code configuration allowed for quick rollout while preserving local workflows. Its asset-centric design enabled consistent logging across complex environments. With mobile capture and real-time dashboards, downtime tracking became both simple and strategic.

As discussed in May’s blog, predictive maintenance begins with good inspection data. This example shows that digital inspection is not just about logging faults. It is about building the data foundation for uptime, operational clarity, and better decisions.

Reframing Inspection as a Strategic Layer

The strategic impact of inspection data extends far beyond fault detection or compliance audits. When inspection processes are digitised and embedded into everyday operations, they create a continuous, high-quality data stream that touches every part of the organisation.

Compliance is no longer reactive and paper-bound. Digital inspections create timestamped, location-based, and role-attributed records that provide a transparent view of regulatory obligations. Audits can be completed without rummaging through binders or chasing teams for paperwork. Structured inspection records ensure defensibility, consistency, and fairness.

Operational performance also benefits. When inspection outcomes are captured in a structured format, they can feed directly into live dashboards, performance reports, and real-time alerts. Teams can gain early visibility into deteriorating conditions, missed procedures, or gaps in work quality. This enables informed interventions that prevent larger issues downstream.

From a safety perspective, digital inspections build confidence. They ensure that frontline checks are consistently executed, that critical steps are not missed, and that corrective actions are tracked to completion. Supervisors can monitor key risk areas without being physically present. Engineers can spot patterns before they become incidents.

Importantly, the cultural shift is profound. Inspection stops being seen as simply a compliance or maintenance task and becomes a data engine. Inspectors evolve from box-tickers to knowledge contributors. Supervisors become decision facilitators. Executives view inspections not just as assurance, but as intelligence. The result is a more responsive, more transparent, and more data-savvy organisation.

Conclusion

The idea that inspection is synonymous with maintenance is outdated. Today, inspection has the potential to be a powerful driver of operational intelligence. As demonstrated in the three case studies, digitised inspection delivers impact in diverse domains:

- It acts as a compliance backbone, ensuring transparency and accountability in contractor governance

- It functions as a shutdown control system, enhancing traceability, coordination, and QA outcomes

- It serves as an operations analytics input, transforming reactive logs into strategic insight for planning and optimisation

These outcomes are not theoretical or aspirational. They are already being realised by organisations that have embraced a structured, mobile, and platform-based approach to inspections.

What unites these successes is the mindset shift. These organisations no longer treat inspections as an administrative overhead. They view them as structured data events that capture real-time, actionable intelligence. They connect inspections to other systems, convert data into dashboards, and use insights to make faster, better decisions.

The Inspectivity Platform enables this transformation with no-code configurability, asset-centric design, and seamless integration. It equips teams at every level with the tools to contribute to a shared understanding of performance, risk, and opportunity.

The final takeaway is clear: stop thinking “inspection equals maintenance”.

Start thinking “inspection equals insight”.