Overview

A leading global chemical manufacturer has transformed its approach to downtime management by implementing the Inspectivity Platform. Facing inconsistencies and a lack of visibility across multiple production sites, the client moved from manual tracking and disparate reports to a unified, digital system for real-time downtime monitoring. The result is standardised asset performance tracking, improved operational planning, and significant gains in data integrity.

Background

The client operates several production facilities and manages a large portfolio of critical equipment. Historically, downtime events were tracked through handwritten logs and Excel sheets, with each site using its terminology and categorisation.

The lack of a unified approach resulted in several key challenges:

- Inconsistent downtime categories across locations.

- Unreliable data, often missing key details like start time, cause, or impact.

- Manual reporting processes that delayed insights.

- No standardised framework to compare or benchmark asset performance.

- Difficulty justifying decisions due to poor audit trails.

These inefficiencies made it difficult for the business to reduce losses, identify bottlenecks, or plan maintenance strategies effectively.

The Challenge

At the heart of the issue was a fragmented system for recording and managing downtime:

- Sites captured data manually using different templates and definitions.

- Production and planning teams lacked timely visibility into loss events.

- There was no structured time usage model to break down the causes of production loss.

- The client had no way to track downtime inheritance across complex asset hierarchies.

Without a consistent method for recording downtime, leadership struggled to drive optimisation programs or respond quickly to emerging performance issues.

The Inspectivity Solution

Mobile Data Capture with Asset Context

The Inspectivity Platform was selected to digitise downtime logging and enable structured, real-time data collection across all manufacturing locations.

With the Inspectivity Go mobile app, field teams can now:

- Log downtime directly at the point of occurrence.

- Record essential metadata including duration, cause, and operational impact.

- Attach supporting photos and notes.

- Automatically tag downtime against pre-defined operational statuses (e.g. operating delay, performance loss, scheduled shutdown).

Each downtime record is linked to the relevant asset within the platform’s multi-tiered hierarchy, allowing for complete visibility across equipment systems and subsystems.

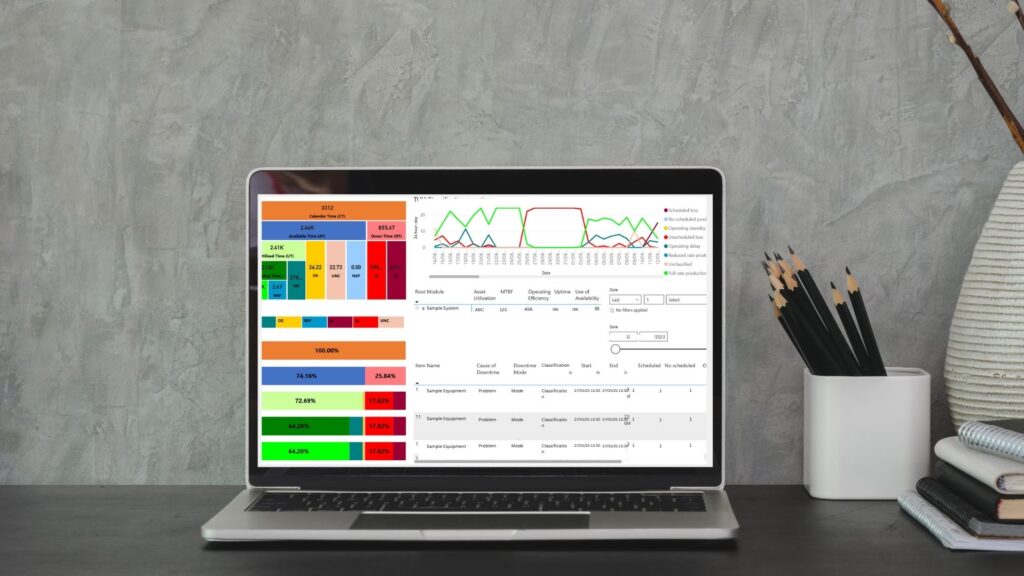

Standardised Time Usage Model

A time usage framework was configured to segment downtime into categories such as:

- Full-rate production

- Performance loss

- Operating standby

- Scheduled and unscheduled losses

This model allows consistent reporting across sites and enables accurate performance benchmarking.

Automation and Reporting

An ETL pipeline was established to automatically transfer downtime data into the client’s Power BI environment. This supports:

- Live dashboards with asset availability and utilisation metrics.

- Automated reporting for plant performance reviews.

- Elimination of manual data preparation.

This has enabled the client to make faster, data-backed decisions with minimal manual intervention.

The key challenge in this use case was rationalising the asset hierarchy and managing the inheritance of downtime – tasks that are incredibly difficult without the right technology. Using the Inspectivity Platform for this kind of operational data capture wasn’t something we originally anticipated, but it turned out to be a perfect example of how inspection is fundamentally about structured data collection. This case study is data collection in action.

Paul Eddison, Inspectivity co-founder

Results & Benefits

The Inspectivity implementation delivered measurable value:

- Real-time visibility into production downtime losses across sites.

- Elimination of inconsistent reporting practices.

- Streamlined root cause analysis for performance loss.

- Faster, more informed decision-making for operations and maintenance teams.

- A scalable framework to support future plant expansions and performance programs.

In the first year following implementation, the client logged over 2,000 downtime events and captured more than 15,000 hours of categorised time usage. Manual reports were fully replaced across all seven production facilities, bringing complete standardisation to downtime tracking. Most notably, reporting turnaround times were reduced from several days to near real-time, enabling a much faster operational response.

About Inspectivity

At Inspectivity, we’re revolutionising the world of asset management with our cutting-edge digital inspection software. Our platform is a versatile mobile and cloud solution, designed to simplify engineering inspection and asset management, all within a single, user-friendly tool.

Trusted by many tier 1 operators and service providers across a variety of sectors, we’ve harnessed technical expertise and industry-specific workflows to create a digital inspection solution that’s a game-changer.

If you’re ready to take your inspection processes to the next level, we’re ready to provide the ideal solution for you.